A quick look back at the year that was 2020 and my goals for Big T’s Chop Shop in 2021.

The Symphony of Chaos

December 2020 was a milestone for Big T’s Chop Shop. It was basically the first month that I’d consider the shop to be fully booked (and then some). Although there were some frantic moments, all of the machines worked really well, and in general, processes and quality held up while shipping a record amount of different projects in all kinds of different materials and industries.

Most days in December, the ShopBot Router, Haas, and Tormach Brothers (1100 S3, and Slant Pro Lathe) were all running away along with all of the manual ops, finishing, coating, shipping, and business operations (invoicing!) to go along with the production.

There was wood. There was metal. There was plastic. Musical Instrument Parts, Bird Resorts, Robot Parts, Automotive Parts, Memorial Plaques, and even some last minute Holiday Decorations all moved through the shop in parallel.

As is always the case in physical manufacturing, not all was perfect, but surprisingly few tears were shed during what was a pretty demanding test of machines, process, and endurance. I’m going to cover a few of the highlights below, and then tee up what’s next for 2021.

Highlight: The Rise of Local Manufacturing During COVID-19

I’m going to dispense with all of the cliche’s about 2020 and get straight to the point:

The disruption of the global supply chain, and specifically, the temporary impediment to the manufacturing dominance of China has created a massive opportunity for North American manufacturers to assert their value.

Trent Shumay, Big T’s Chop Shop

At our shop, two key things happened this year as a result of the pandemic:

- The de-facto standard of sending even early stage product prototypes and short run manufacturing projects offshore became far less attractive and in some cases, even impossible.

- People had time. Time to think, and dream, and to chase down the product idea they had always had in the back of their mind or stashed in a sketchbook somewhere.

The question now is whether this trend will continue in 2021, or if we will see a return to our old ways once the pressures of the pandemic subside. At our shop, we are visualizing this as an opportunity to retain the gift that 2020 gave us. Going forward, we need to continue to demonstrate that there are advantages in continuing to do this work right here in North America.

I believe the following principles are key:

- Efficiency. We need to remember what it was like to be hungry for the work needed to keep our shops alive during the pandemic. Old practices like “take it or leave it” pricing that were endemic to North American manufacturing need to be replaced by collaboration and optimization between design and manufacturing processes. We need to work together to arrive at mutually beneficial pricing that reflects the value of the tighter feedback loop and better communication afforded by working with local partners.

- Productivity Innovation. We need to fight back against cheap labor, lax environmental standards, and dubious material origins by investing in the technology and processes that let us leverage our best thinkers to create higher levels of productivity to utilize our infrastructure. We need to stabilize the availability and cost basis of raw materials and avoid ridiculous political shenanigans like tariffs and taxation, so we can focus solely on productive and free exchange of ideas and goods with our partners (especially throughout North America).

- Maximizing Use of Capital. Recovery will not be without pitfalls. Money is cheap right now, and that’s a massive opportunity to fill holes in capability and optimize costs with the available capital and incentives. We can leverage this opportunity to come back stronger. But, there is also a huge risk of over-extension, and not applying the capital to solve the right problems. Using capital to build more efficient process and capacity is good. Using capital to prop up old ways of thinking and doing business is very dangerous right now.

Highlight: Upgraded Production Capacity

We took delivery of two new machines during 2020. Both made a massive difference to the production capacity and capabilities at the shop. Frankly, probably both were overdue, but 2020 and the increased demand for services were the catalyst to make these deals happen.

Haas TM-1P

Our Haas TM-1P has settled into life as the “production workhorse” at the shop. Although operators of larger machines would likely laugh at that statement (the TM-1P is sort of the “baby” Haas in the lineup) it has been a game changer at the shop.

There are a number of things that we love about the TM-1P:

- Horsepower and Speed – The machine is capable of removing massive amounts of material, particularly in aluminum. Large automotive parts (like wheel centres) require you to machine large blocks down into relatively svelte final forms, and if you can turn bigger tools, with more cutting flutes, at deeper depths, the return on investment is obvious.

- Automation – The Haas machine is pretty self sufficient once a program has been verified. It can change cutting tools automatically, and has a variety of sensors that can detect issues with a lot of the key failure modes like low air pressure, power, and other unexpected scenarios. This has enabled us to do some “lights out” machining where proven programs can just continue running on their own either overnight or with very minimal supervision.

- Accuracy – Again, by absolute standards, maybe not as accurate as very expensive machines, but a repeatability of 0.0002″ on mechanical motion is absolutely amazing for us. Parts come out of the machine with a great finish, and very tight tolerances and we have been very happy with the output.

Tormach 15L Slant Pro Lathe

A year ago, if you would have said making bolts, stand offs, or basic shafts would be “a thing” most people might not have taken you that seriously. Nobody in their right mind would do anything but order bags of bolts and hardware from Alibaba, right?

Fast forward a year into a pandemic where half the bins in the hardware section at your local hardware store are empty, and things start to look a lot different. That said, we’re not super bullish on the long term prospects for manufacturing aluminum stand offs, but right now, it’s a thing. It’s also a great example of the value a local manufacturing partner can have in a pinch.

Highlight: Building a Business

Personally, and professionally, for me, 2020 was a tough year. Other significant investments I had made in hospitality businesses and associated enterprise were absolutely hammered by what happened. I really needed an outlet to both be productive, and build a business that made sense in the new world that had been so quickly thrust upon us.

Machining and manufacturing had always been a big part of what I was passionate about at the IoT Design Shop, which was the “think tank” from which Big T’s emerged.

The criteria for making a living machining stuff is fairly black and white:

- I need to find enough customers, and do high quality work for them at a price point they accept.

- The revenue from that needs to be enough to sustain and grow the business.

Is it working?

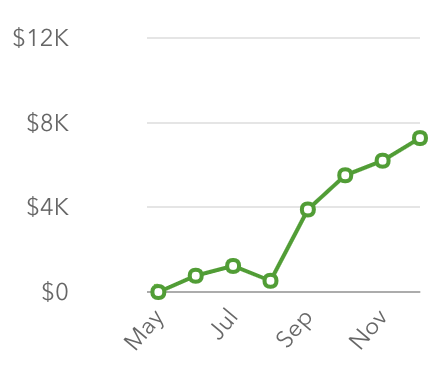

Maybe? The jury is still out. That said, the right thing is happening. Here’s what the graph of 2020 looked like in terms of revenue from manufacturing at the shop.

Basically, in June, I sort of looked myself in the eye and said, “Ok. You putter around with this stuff as part of other projects at the IoT Shop, but you keep saying you think you can make a run of it. Are you in?”

So, I started marketing, scouring the work and RFQ sites, contacting local companies that looked like maybe they could use a prototype guy, etc. and started drumming up business.

By Dec, this work grew to just shy of $8K a month in revenue. Let’s be honest – that’s a pretty paltry amount. However, it’s also around 800% higher than where we started in June in terms of manufacturing revenue. So, that’s not too shabby.

The other big thing, is that with affordable machines, and low overhead, that $8K a month is profitable. Again – not by much. But, it’s basically a sustainable system that I can build on to grow the business.

Next Steps

The big question, of course, is where the trajectory of that sales curve starts to taper off. Currently, January is getting booked up very quickly, and shows no signs of falling off, so risk in terms of demand doesn’t seem to be an immediate concern.

The bigger issue may be whether the growth of that sales curve can continue to be maintained while staying almost impossibly lean. With a one-man-many-machines set up as we have today, the system is sustainable. But, can it grow much more without adding capacity and overhead, and if not, what is the impact of taking in some more of capital and ramping up?

2021 Strategy

Although there’s no way to know the answers to all the questions ahead of a business, you still need a plan. Here’s the stake I am putting in the ground for 2021, and the strategy for Big T’s Chop Shop:

- Maximize Use of Capital – One of the big moves we’re making in January is a literal one – To our own facility that we purchased in December. This means that rent expense normally going to someone else is fed back into the empire to grow. Ideally, the real estate increases in value as well as the years go by, and this is a double-win. Rent is currently our single biggest line-item expense, and this move will let us leverage the cheap capital currently available to reduce that significantly.

- Automation – One lesson learned from the Haas purchase is that there is incredible value in automation. All of our existing machines will be upgraded with the available automation tools – tool changers, automatic closers, material handling, probing, and more. This means that the work of one operator can go much further for what is comparatively a relatively low cost investment.

- Robotics and Machine Learning – Robot tenders, computer vision, and industrial IoT are rapidly becoming domesticated to the point where they can be integrated into workflow even on the smaller machines that we are operating today. We believe that leveraging our specific aptitude in this areas is the “secret sauce” that will allow a small shop to punch well above its weight.

- Stay Hungry and Humble – This mantra, borrowed from my first company, Finger Food Studios, is more relevant today than ever. One of the lessons of the pandemic has been to understand what is truly important. To me, this is providing services of value, at value. If we can continue to provide high quality work to our partners at a price that works for both of us, then there’s no reason we cannot continue to grow and continue to extend the foundations of a responsible business model.

Myself and my robotic companions at Big T’s Chop Shop would like to wish you and yours a happy and healthy 2021. We sincerely look forward to seeing what the year may bring, and working with everyone this year.

Trent Shumay – Big T’s Chop Shop